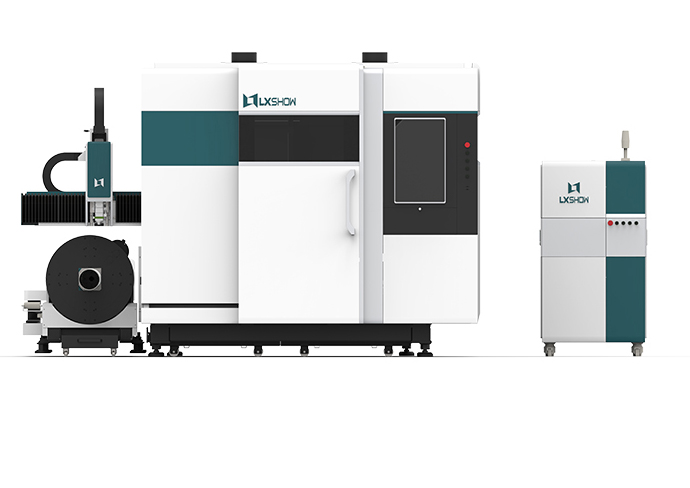

Fiber Laser cutting machine

The laser welding machine is suitable for welding of gold, silver, titanium, nickel, tin, copper, aluminum and other metal and its alloy material, can achieve the same precision welding between metal and dissimilar metals, has been widely used in aerospace equipment, shipbuilding, instrumentation, mechanical and electrical products, automotive and other industries.

- 20+ years manufacturing experience

- Inspect all incoming materials.

- 6 inspectors will in charge of all inspection work

- All the cutting machines will be inspected before delivery.

Source Screw Air Compressor Systems Equipments Cooperating

Share Global Air Compressor Market from Zollant - a Manufacturer

Since 2002

Air Compressor Market size was USD 75.5 billion in 2019 and will witness a CAGR of 5.2% between

2020 and 2026. The industry scope covers various categories of the product including air compressors

for home appliances, tire inflators, automotive compressors for air conditioning and air brakes, construction

equipment, medical and industrial air compressors for driving pneumatic types of machinery.

PM VSD Air Compressor Advantages:

2.The Latest Generation High Efficiency Permanent Motor

3.The Latest Generation Super Stable Inverter

4.Wide Working Frequency Range To Save Energy

6.Low Noise

Model | ECO-1000/1500/2000W |

Laser power | 1000/1500/2000W |

Center wavelength | 1070+-5nm |

Laser frequency | 50Hz-5KHz |

Work patterns | Continuous |

Electricity demand | AC220V |

Output fiber length | 5/10/15m (Optional) |

Cooling method | Water Cooling |

Dimensions | 1150*760*1370mm |

Weight | 275kg(About) |

Cooling water temperature | 5-45℃ |

Average consumed power | 2500/2800/3500/4000W |

Laser Energy Stability | <2% |

Air humidity | 10-90% |

Contact Us For A Quick Quote

Fiber Laser Marking Machine

Design Support

Email Support

CNC Cutting Solutions

Local Team Support on Laser Marking Machine

Customized Laser Cutting Machine For Cosmetics

1.The energy density is high, the heat input is low, the amount of thermal deformation is small, and the melting zone and the heat-affected zone are narrow and deep.

2.High cooling rate, which can weld fine weld structure and good joint performance.

3.Compared with contact welding, laser welding eliminates the need for electrodes, reducing daily maintenance costs and greatly increasing work efficiency.

4.The weld seam is thin, the penetration depth is large, the taper is small, the precision is high, the appearance is smooth, flat and beautiful.

5.No consumables, small size, flexible processing, low operating and maintenance costs.

6.The laser is transmitted through fiber optics and can be used in conjunction with a pipeline or robot.