Fiber laser cutting machines Buying Guide

A laser cutting machine is one of the most coveted tools in the manufacturing industry. The versatility that comes with a laser cutting machine makes it very functional equipment. The popularity of a laser cutting machine is mainly owed to its ability to cut through many materials with a high level of accuracy. A CNC laser cutting machine is equipped with a thin laser beam that gives precise detail.

We understand that buying a sheet metal laser cutting machine can be an overwhelming task. Whether you are looking for a metal laser cutting machine for home or industrial use, this laser cutting machine buying guide will point you in the right direction. First, here is an overview of what it covers.

- What is a laser cutting machine?

- The history of laser cutting technology

- What are the applications of a laser cutting machine?

- Is a laser cutting machine worth the hype?

- Types of laser cutting technology

- Advantages of laser cutting over traditional mechanical cutting

- Advantages of laser cutting over plasma cutting

- How can you choose the best laser cutting machine?

What Is A Laser Cutting Machine?

The laser cutting technology is widely applicable in industrial processes that require millimeter-precise cutting and trimming. A laser cutting machine has a laser beam that melts to cut material using a thermal process. The assist gas of the laser cutting material removes the excess material after cutting through.

A laser cutting machine is one of the most precise and clean cutting technology.

The History of the Laser Cutting Technology

Carbon dioxide laser cutting technology was the first to be introduced, and it has continued to dominate the market. Fiber laser cutting technology was introduced in 2008 as an alternative laser cutting technology.

Buying a laser cutting machine is one of the best investments in the manufacturing industry. If you choose the best CNC metal laser cutting machine, the benefits will impact your production process.

What Are The Applications Of A Laser Cutting Machine?

One of the most challenging questions is ‘do I need a laser cutting machine?’ for different reasons, buying a laser cutting machine is a massive investment, especially if you have a manufacturing facility.

A laser cutting machine is applicable in many industrial processes. For instance, you may not need a press machine to cut or trim materials if you have the precision of a laser cutter. Accordingly, many manufacturers use a turret punch to create holes and shapes in different materials. The problem is that a turret punch requires tooling, making it limited to small-scale production.

Jewelers use a laser cutting machine to make precise cuts in beautiful pieces. Additionally, the machine is used in the automotive, agriculture, and medical industries to deliver precision when cutting through different materials used in manufacturing various components.

Is A Laser Cutting Machine Worth The Hype?

Any company that does not have a laser cutting machine will be forced to outsource such tasks to another firm with the equipment. This situation is okay if you have a flexible schedule and lead time. If you have tight deadlines to meet and high production, a laser cutting machine becomes a business necessity.

How do you know if buying a laser cutting machine is worth the investment? Do you have a manufacturing facility? Track your monthly expenses on laser-cut parts. This aspect alone is enough to see the value of owning a laser cutting machine.

If you are still unsure whether a laser cutting machine is worth the hype, ask yourself these questions.

- What is the cost of subcontracting laser cutting projects?

- How much production will an in-house laser cutting machine bring?

- What is the price of a laser cutting machine, and how does it compare to outsourcing the services?

- How does owning a laser cutting machine affect lead times?

Types of Laser Cutting Technology

There are two types of laser cutting technology in the market. The traditional CO2 laser cutting machines are the most used. However, there is new fiber cutting laser machines.

CO2 laser cutting machines are mainly used in metal fabrication industries. They work by directing electricity through a resonator filled with carbon dioxide and other gases. CO2 laser cutting machines use mirrors to focus the beam to the desired parts.

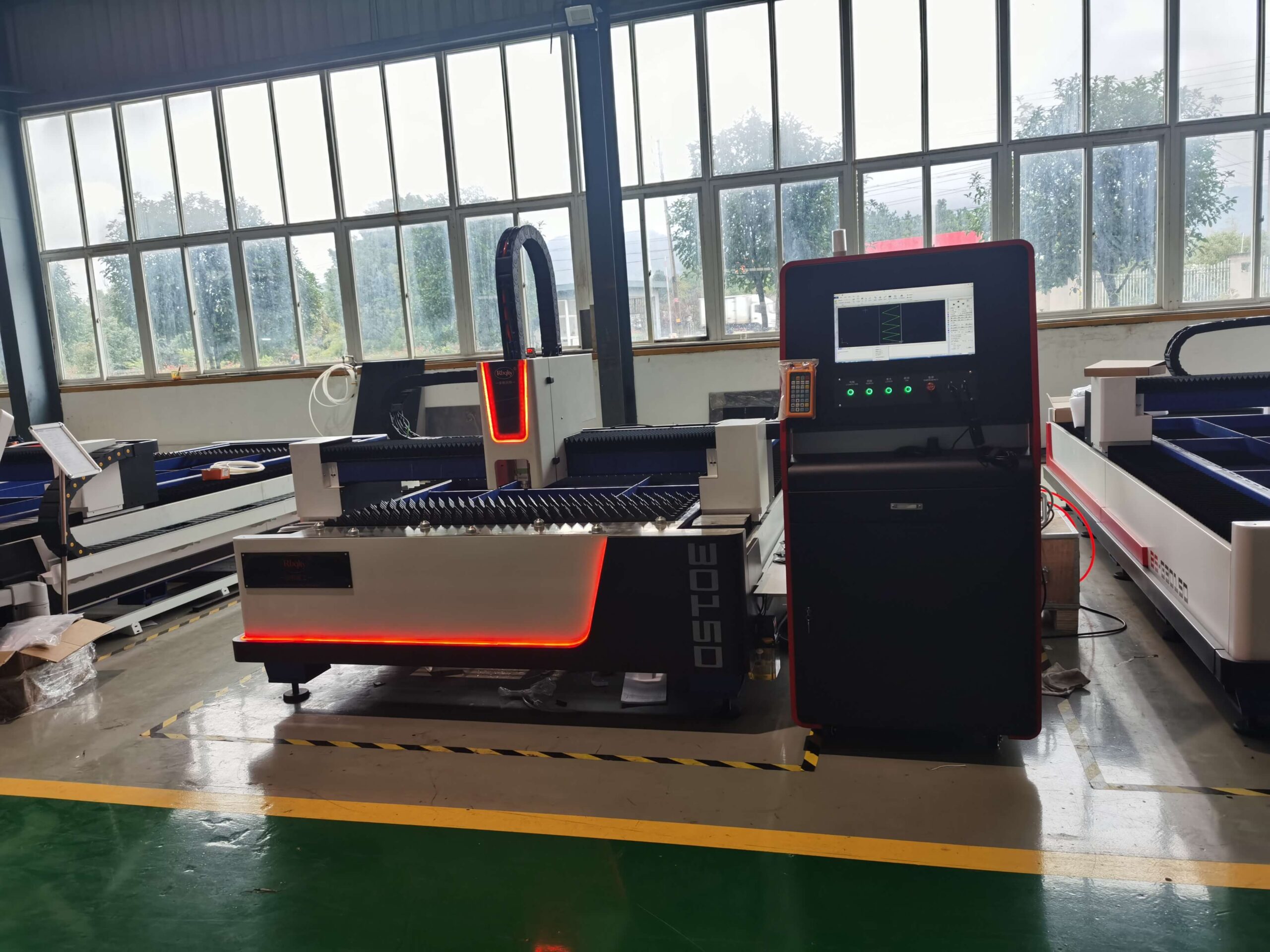

Fiber laser cutting machines use banks of diodes to create a beam that is directed through a fiber optic cable. The fiber laser cutting technology was first introduced in 2008. It comes with a low operating cost and high speed than the CO2 laser cutting machine.

Fiber laser cutting machines are nowadays designed with powerful lasers that can cut through thick materials with impressive speed. This aspect makes fiber laser cutting machines more reliable, precise, and popular.

Advantages of Laser Cutting Over Traditional Mechanical Cutting Tools

- High-quality cutting at a faster speed

- Little part deformation

- Greater cutting accuracy

- Reduced contamination and damage

Advantages of Laser Cutting Over Plasma Cutting Technique

- Higher cutting accuracy

- Fewer heat-affected areas with smaller slits

- Energy-efficient

- Environmentally friendly

- Suitable for cutting thinner materials

- Strict tolerance

- Suitable for accurate cutouts

How Can You Choose The Best Laser Cutting Machine?

Choosing the best laser cutting machine can be an overwhelming task. If you are a first-timer, there are many things you should consider to ensure you do not get a raw deal. Here is the simplified laser cutting machine buying process.

Laser cutting technology is designed to cut through a wide range of materials. That is why you will find both metal and non-metal laser cutting machines.

First, determine the materials you want to work on before you decide on the laser cutting material to buy. In this category, you can buy a metal laser cutting machine, fabric laser cutting machine, plastic laser cutting machine, or wood laser cutting machine.

Do you want a fiber metal laser cutting machine or a CO2 metal laser cutting machine? Find out the advantages and disadvantages of each to see the one that suits your projects.

What is your budget? Laser cutting machines retail at different price points. Find out the following for the best deals:

- Metal laser cutting machine for sale

- Metal laser cutting machine price

- Small laser cutting machine price

- Cheapest metal cutting laser

- Metal laser cutting machine price in India

- Metal laser cutting machine price in Pakistan

- Metal laser cutting machine price in Bangalore

- Used metal laser cutting machine price in India

The Bottom Line

Laser cutting machines are some of the most versatile and functional industrial tools. Found in both fiber laser cutting technology and CO2 laser cutting technology, you can never miss one in an industrial facility that requires cut or trimmed parts. If you want to purchase a laser cutting machine, use this buying guide to make an informed buying decision.